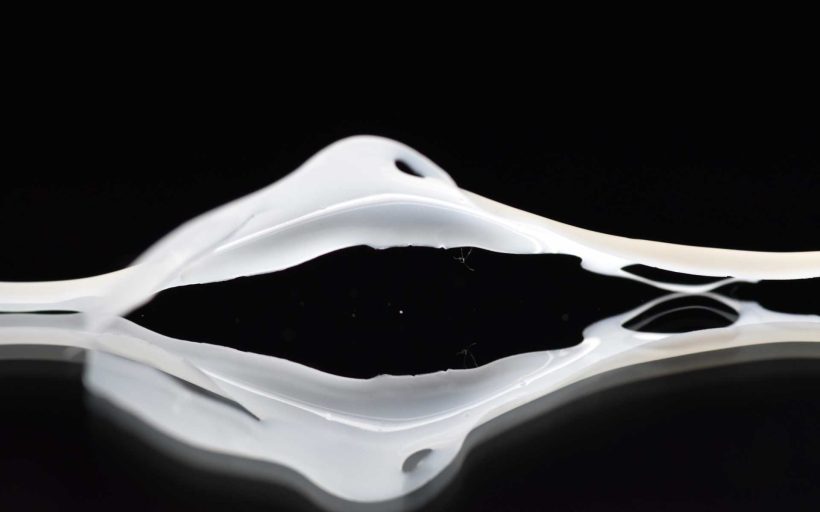

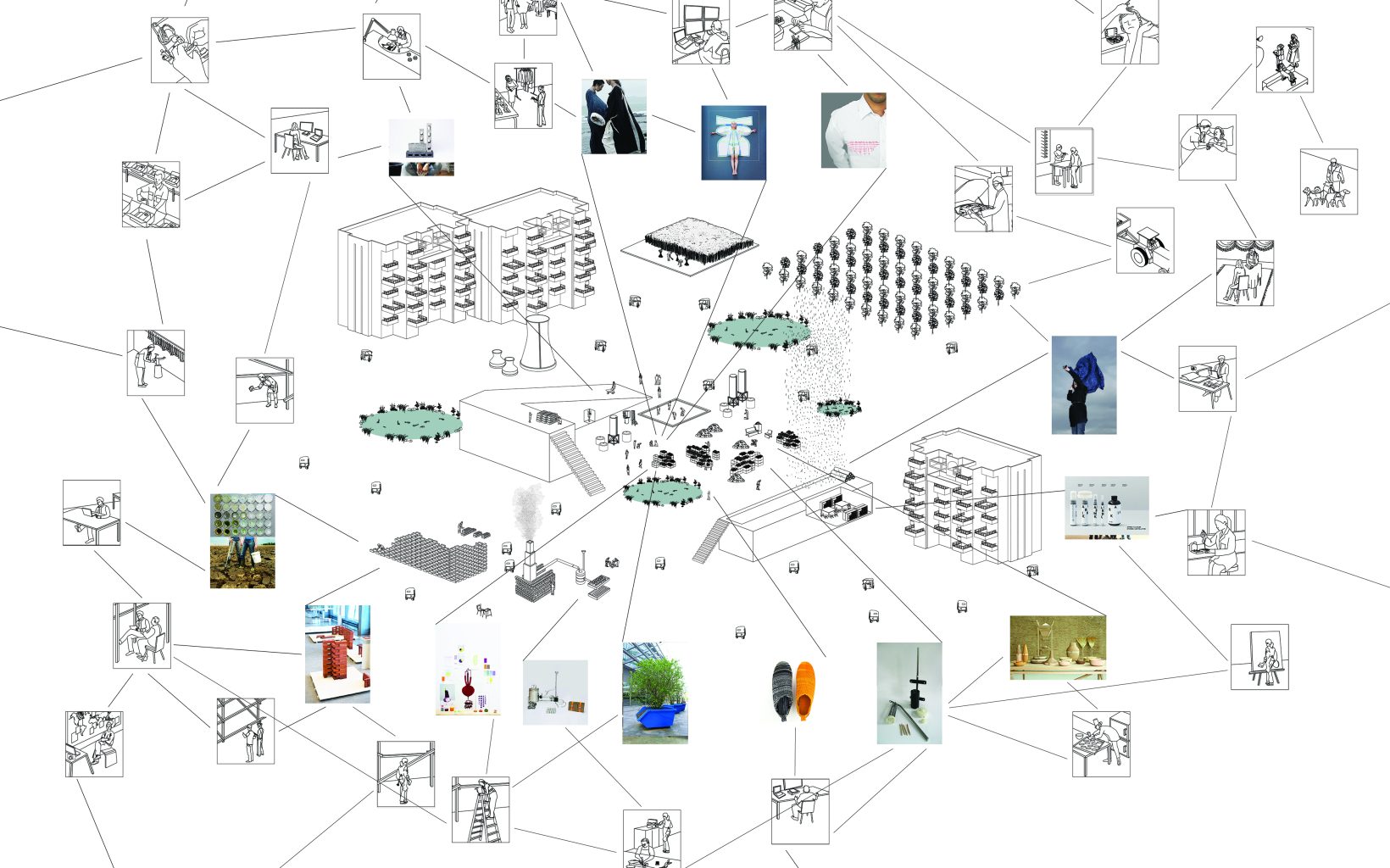

Turning the global manure problem into a new sustainable and local source of raw materials for the paper, plastics and fibre industries.

Long Description

With Mestic® we make bio-plastic and fibers directly from cow manure. Intensive farming in many parts of the world oversaturates the soil with nutrients from manure. This excess manure is an acute problem which needs to be dealt with in order to avoid major environmental catastrophes. At the same time, the Dutch government arranged the so called “National Raw Materials Agreement”, a commitment by 180 of our biggest companies to use 100% recycled and local materials by 2050. So, why not approach manure as a source material for our manufacturing industry and tackle both needs? Now that’s what we do with Mestic®! How does it work? With the method that we developed we produce a dissolving-grade-pulp from cow-manure. This pulp acts as the raw ingredient for cellulose-derivatives like cellulose acetate (bio-plastic); and viscose or similar fibers. The fractions of manure that cannot be pulped are used to win organic solvents and other process-chemicals used in the method, and with the leftover fractions we make an organic fertilizer that can compete with synthetic fertilizers. Therefore all of manure is transformed into valuable useful materials. By implementing Mestic® we will turn the global manure problem into a new sustainable and local source of raw biodegradable materials. Making multiple industries circular at the same time, significantly reducing the carbon footprint of all industries involved. (For example, producing Mestic® fibers results in a reduced GWP of 7100 CO2 eq./t when taking into account effects from fiber-production, shipping and emissions from cows)

Share on social media.

Facebook

Twitter

LinkedIn

Mail