Oricla is a fabric built from the edge loss fabric that are thrown away in tons in shirting factories after the cutting process.

Long Description

The motivation for developing Oricla was the will to find a solution to a very serious problem in the clothing industry all around the world: the discard of textile scraps after the cutting process. Tons of this waste is produced everyday in clothing factories. These remnants represent, depending the kind of garment, from ten to fifteen percent of the cut fabric. This means that ten to fifteen percent of all energy and resources used for producing the fabric are thrown away. In a mid-size shirting factory that produces thirty thousands of shirts a month, forty thousands meters of fabric are cut. This means that between four thousands and a half and six thousands of meters of fabric “chopped” are discarded per month.

As in a cradle to cradle system, all the energy and resources used for making the fabric will be conserved and revalued.

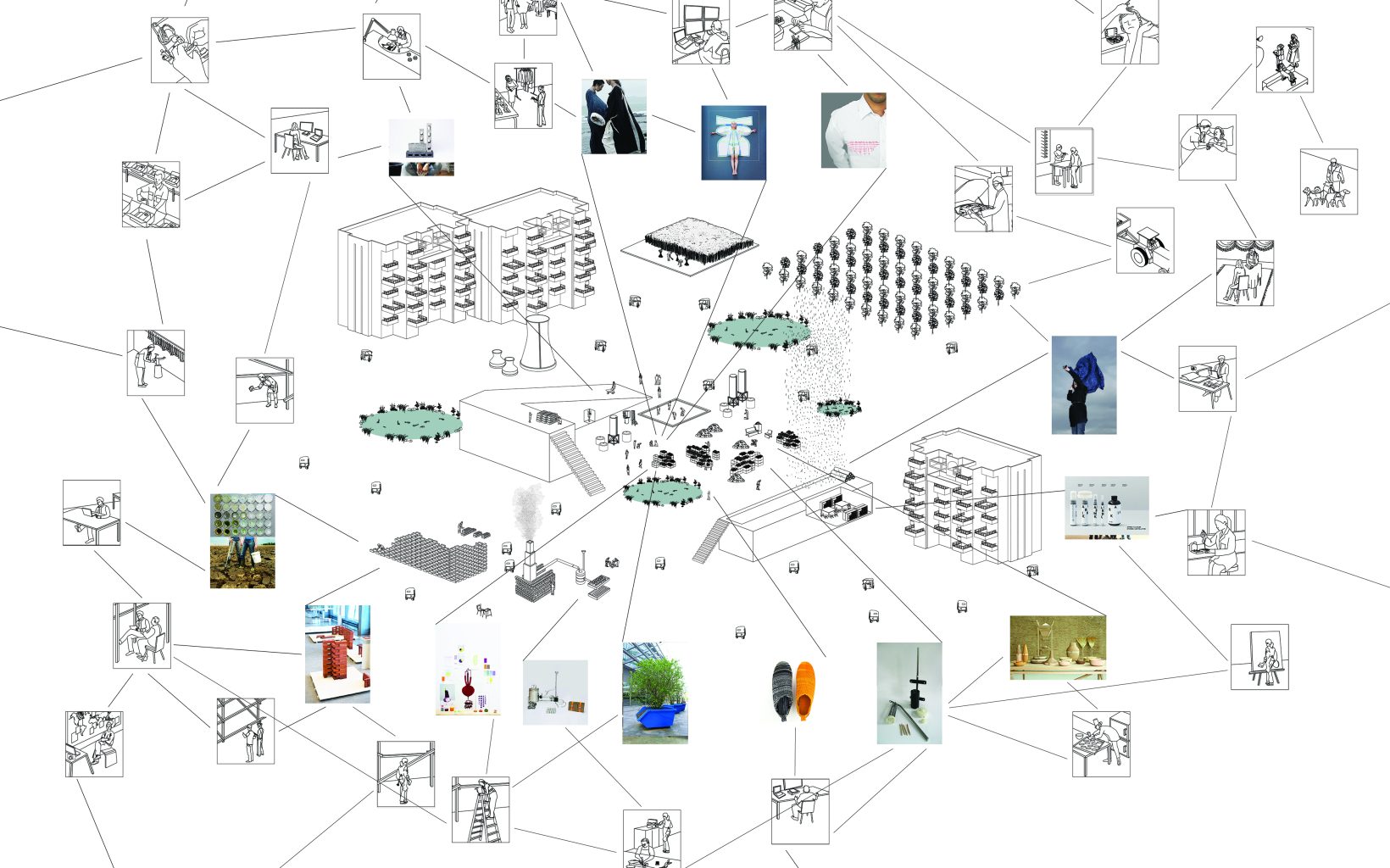

Sewers in sewing machines make Oricla, so it can be easily scaled as a social technology by building a net of sewers around the industrial areas where the waste is being produced, that can build the fabric inside their homes. As in symbiosis relationships seen in nature, where small living beings feed themselves up from larger living being’s remnants, we want to build a system were what is waste for industry is source of income for communities.

These edge losses can also be distributed as yarn for being used in other products such as knitting, hand crafts industry, and the construction of other fabrics for accessories and decoration markets.

Share on social media.

Facebook

Twitter

LinkedIn

Mail