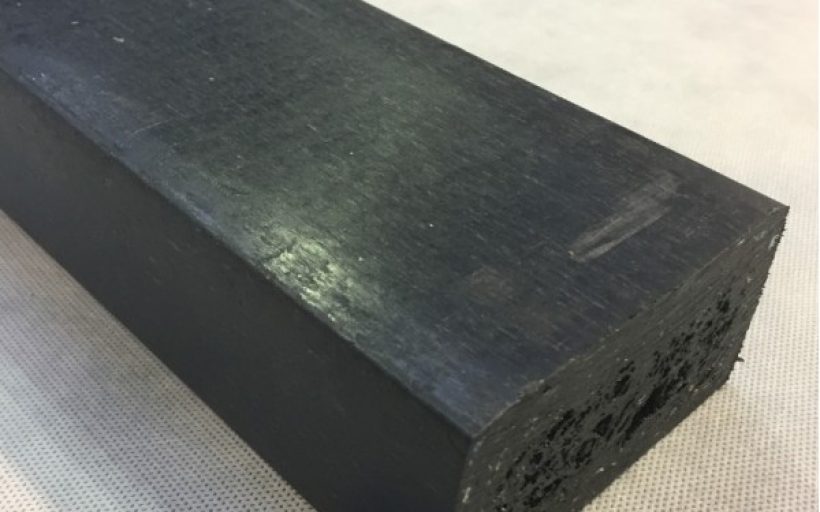

We use our innovative technology to transform plastic garbage into durable and long lasting plastic lumbers, used for building and construction replacing timber.

Long Description

9 Million tons of waste plastics and packaging materials ends up in to our oceans every year, same time we lose over 13 million hectares of forests every year due to deforestation, we are a social enterprise We are a green social enterprise established to address the challenges of post consumer plastic pollution, waste management, deforestation and climate change.

We use our innovative plastic extrusion technology to recycle and transform post consumer waste plastics into durable and long lasting plastic lumbers, Plastic lumbers are affordable alternative to timbers, hence reduces the need for building material manufactured from wood, helping to preserve forests and cut down on deforestation and further mitigation of Climate change. Plastic lumbers which are ideal product for building, construction and furniture making are normally made in 10ft on average and shaped either round or square.

Our technology “Waxy 2 Technology” is an environmental friendly plastic extrusion technology that uses profiled waxy innovation in the extrusion process set at different temperatures, the technology helps plastic materials of different polymers reach their melting point quickly while retaining their original stability, helping to use less energy which lowers production costs, enabling production of plastic lumbers which are 32% less compared to price of timber, the technology converts more than 12 different types of plastics and packaging materials, producing durable, long lasting, termite resistant plastic lumbers used in building and construction estimated to last more than 40 years without replacement whether used in sunny areas, marine or in water applications.

Share on social media.

Facebook

Twitter

LinkedIn

Mail